Japanese / English

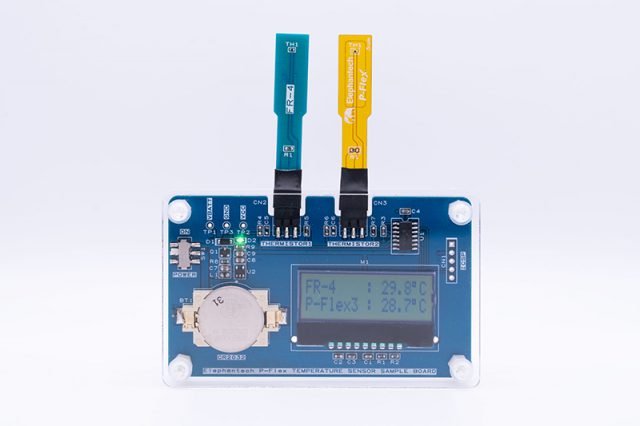

Benefit of using P-Flex® to speed up the thermal response time of temperature sensor ICs and thermistors

High thermal responsiveness (i.e., the ability to detect temperature changes in a shorter time) when measuring temperatures has many advantages, as it allows for quicker control in equipment that is triggered by temperature changes.

The following is an example of an air conditioner that can be easily visualized.

– Reduced electricity costs due to fine-tuned temperature control

– Improved comfort for humans

– Improves safety by immediately detecting heat generation due to equipment malfunctions

To improve thermal response time, we focused on thermal mass.

– Thermal response time increases when materials with high thermal mass surround the sensor

– Materials with high thermal mass respond more slowly to temperature changes than those with low thermal mass (e.g., insulation)

In addition, since most temperature sensors are supplied in surface-mount PKGs, the IC must be mounted on a board. The substrate for mounting must have low thermal capacity.

Advantages of Using Flexible Substrates

( Benefit 1) Thin flexible substrates can quickly respond to changes in air temperature due to their small thermal capacitance.

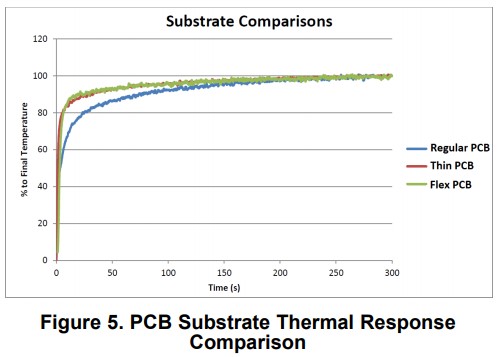

The graph below shows that flexible substrates have a short thermal response time and can measure temperatures quickly.

Texas Instruments Application Report – SNOAA03:Layout Considerations for Wearable Temperature Sensing

Horizontal axis: time, vertical axis: thermal response time, green line: flexible substrate, red line: thin rigid substrate, blue line: rigid substrate

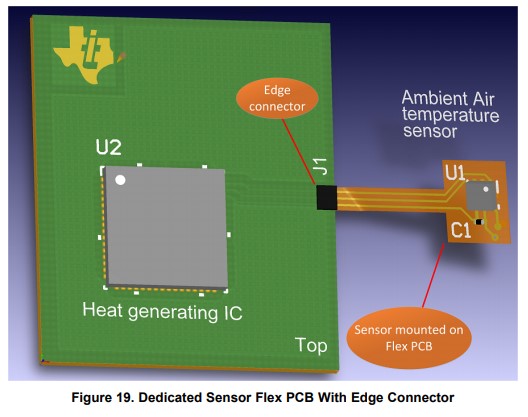

( Benefit 2) Separation from the main board can reduce the influence of heat from the processor and power supply and the fan.

By separating the temperature sensor from the main board, where heat-generating components such as a high-speed processor are installed, the influence of the heat can be reduced and the temperature can be measured accurately.

Texas Instruments Application Report – SNOA967ATemperature sensors: PCB guidelines for surface mount devices P17

Texas Instruments Application Report – SNOA967ATemperature sensors: PCB guidelines for surface mount devices P17

(Benefit 3) Flexible PCBs can be used to extend the distance, enabling placement close to the desired location for measurement.

If the temperature is not to be measured on the main board, in other words, if the temperature is to be measured in a different part of the enclosure, a thin, bendable flexible board can be used to extend the measurement distance to the desired location.