Japanese / English

Advantages of Using P-Flex® for MEMS Microphones

MEMS microphones are used in various electronic devices including smartphones because of their small size and suitability for mass production. Most of them are surface-mount type and are mounted on PCBs.

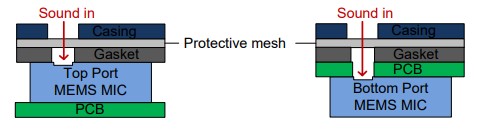

Types of MEMS Microphones: Top Port Type and Bottom Port Type

MEMS microphones have a small hole in the case to capture sound. If the hole is on the top cover side, it is called a top-port type, and if it is on the PCB side, it is called a bottom-port type. The figure here is a cross-sectional view of a MEMS microphone from Cirrus Logic’s application report. (Left: Top port type, Right: Bottom port type)

Two advantages of using P-Flex®, which is thin and has a high degree of form-flexibility

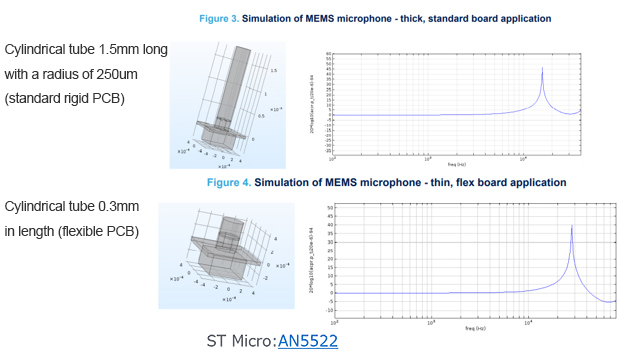

To maximize sound performance, the thickness of the case, gasket (*), and protective mesh layer in the sound capturing area should be reduced. The thickness of the PCB also has an important factor since the bottom-port type sound is drawn in through the PCB. It is recommended that the sound input section should ideally be 0.5 mm thick, with a maximum thickness of 4 mm (Microchip application note).

By mounting the MEMS microphone on P-Flex®, a flexible substrate made of 25µm (polyimide and thinner substrates), it is possible to accommodate the recommended thickness of the input portion of a bottom port microphone type.

P-Flex® can also be used to separate the microphone from the main PCB to prevent vibration coupling for both top-port and bottom-port microphones.

It is made possible to separate the MEMS microphones from noise sources such as buzzers, motors, and mechanical switches mounted on the main PCB.

(*)Terminology: A gasket is something that is pinched and compressed to seal the gap and at the same time prevent leakage of fluid or entry of foreign matter from the outside

Difference in frequency response with substrate thickness

In addition to these features of flexible substrates, P-Flex® has the advantage of being environmentally friendly due to the Pure Additive manufacturing process.