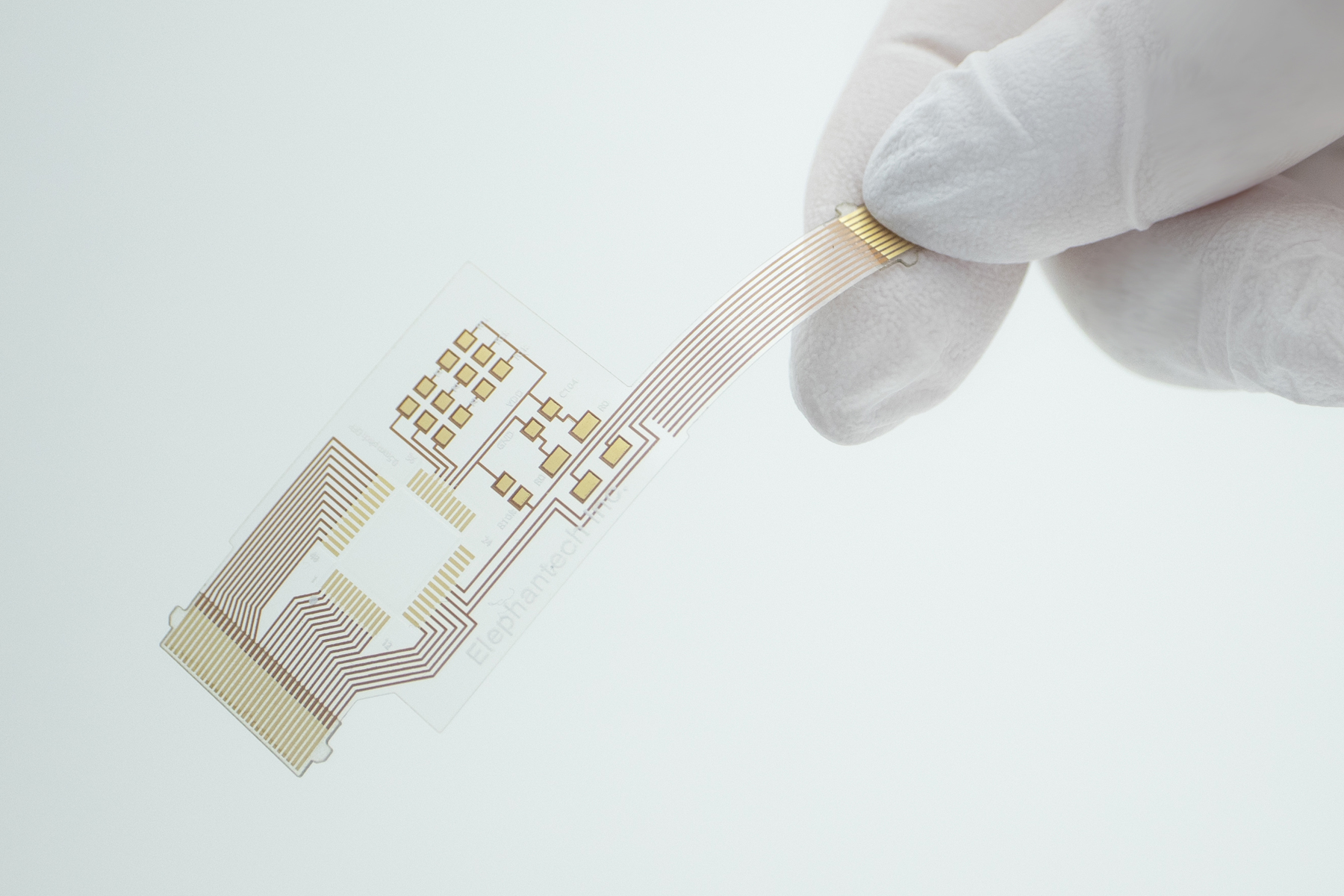

At Elephantech, we will continue the advancement of an environmentally friendlier manufacturing method for mass-production that uses inkjet printing technologies to print metal nano-ink exclusively onto areas where it is required.

Moving forward, we would lik to accelerate the broadening of manufacturing possibilities in anticipation of the expansion and social implementation of additive manufacturing.

Launch of Ink Discharge Evaluation Service

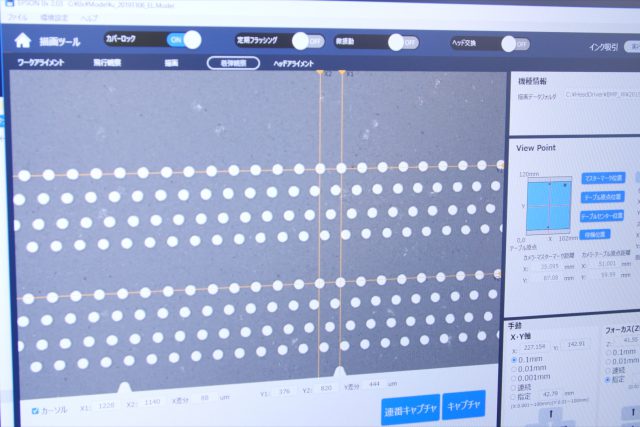

As a first step down that path, we have launched an ink discharge evaluation service that makes full use of the inkjet printing technologies we have accumulated over the years.

More than just an ink discharge evaluation, this service will bring you all of Elephantech’s experience with the mass-production of printed electronics as we make proposals to improve the ink’s characteristics and aim to expand the applicable fields for inkjet printing.

Our ink discharge evaluation service uses a high-performance printhead made by Seiko Epson Corporation (hereinafter “Epson”) to provide a speedy evaluation of an ink’s performance for inkjet printing purposes and acts as a one-stop solution covering everything from ink reception to ink discharge evaluation and report writing.

In anticipation of the expansion and social implementation of additive manufacturing brought by inkjet printing

With characteristics such as having low environmental impact, being digital friendly and having high design freedom, inkjet printing technology is a perfect match for additive manufacturing.

As a company, Elephantech promotes the use of inkjet printing technologies for printed electronics, but we also see value in developing the technology for various fields such as biosensors or optics.

This service is ideal for people and companies seeking to evaluate the ink discharge performance for the ink they are developing and gain a specialist’s opinion on its suitability for inkjet printing.