October 7, 2020

Nisshinbo Mechatronics Inc.

Elephantech Inc.

Nisshinbo Mechatronics and Elephantech Agree to Develop Molded Parts for ADAS Vehicles Using IMPC® Technology

Nisshinbo Mechatronics Inc. (based in Chuo-ku, Tokyo and headed by CEO Toshihiro Masuda, hereinafter referred to as “Nisshinbo Mechatronics”) and Elephantech Inc. (based in Chuo-ku, Tokyo and headed by CEO Shinya Shimizu, hereinafter “Elephantech”) have concluded a basic agreement to develop wiring-integrated molded parts for ADAS vehicles by combining Nisshinbo Mechatronics Group's injection molding technology and Elephantech's IMPC® three-dimensional wiring technology*.

The Nisshinbo Mechatronics Group will, based on its injection molding technology, electronics technology and automotive parts manufacturing know-how, incorporate Elephantech’s IMPC® technology to accelerate the development of various in-vehicle molded parts in which resin, wiring and functions are integrated with each other. Prototypes of molded parts with integrated wiring for ADAS vehicles have already been made and we are moving onto developing for mass production aiming for a 2023 start.

To realize a safe and reliable future for mobility in society, the importance of in-vehicle sensing is on the rise. Furthermore, for increasingly sophisticated automated driving in the future, a large number of parts and manufacturing processes will be required. Moving forward, finding a way to integrate a wide variety of sensors and other components into vehicles while decreasing the number of parts and shortening manufacturing processes will be a challenge.

Elephantech’s IMPC® technology is seen as a potential solution for this problem and its unique wiring printing technology that combines inkjet printing and electroless copper plating presents a competitive advantage. Furthermore, IMPC®, a technology for manufacturing 3D wiring, will be developed by combining the differentiated wiring printing technology and the film insert molding technology owned by Nisshinbo Mechatronics group companies. By combining the core technologies of both companies, the integration of resin molded parts and wiring will make it possible to incorporate a large number of functions while reducing the number of parts. The two companies will continue to plan and develop new products by applying and collaborating with each other's technologies.

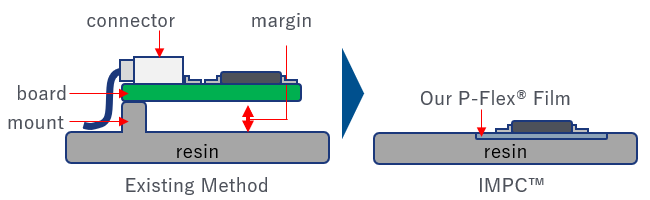

IMPC® (In-Mold Printed Circuit) Technology

As opposed to conventional partial optimization structures where resin and electronic circuits were designed and manufactured separately before being combined, our design and manufacturing solution involves integrating and optimizing parts as a whole. By integrating the resin and the circuitry, a wider range of optimized designs can be achieved, resulting in various advantages such as reduced weight, thickness and cost.

Company Overview

| Company Name | Nisshinbo Mechatronics Inc. |

| Headquarters | 2-31-11, Ningyo-cho, Nihonbashi, Chuo-ku, Tokyo |

| Capital | 4 billion JPY (as of December 31, 2019) |

| Main Business | Development, manufacture, and sale of Molding products Development, manufacture, and sale of customized machines Manufacture, and sale of Precision Parts for Automobiles |

| URL | https://www.nisshinbo-mechatronics.co.jp/english/ |

<Press Contact>

Nisshinbo Holdings Inc. IR & Public Relations Group

TEL +81-3-5695-8854

<For inquiries about our business and products>

Nisshinbo Mechatronics Inc. Business Administration Department

TEL +81-564-55-1111

| Company Name | Elephantech Inc. |

| Headquarters | 4-3-8, Hatchobori, Chuo-ku, Tokyo |

| Capital | 310 million JPY |

| Main Business | Development and servicing of production technologies for printed electronics Development of manufacturing technologies using additive manufacturing |

| URL | https://www.elephantech.co.jp/en/ |

<For inquiries about IMPC® technology>

Elephantech Inc. Public Relations Officer