November 24, 2021

Elephantech Inc.

Elephantech's P-Flex® Design Win for FUKUDA's Air Leak Test System

for Packaging Containers MSQ-2000 series

Elephantech Inc. ("Elephantech") is pleased to announce that the company's Flex PCB P-Flex® has been successfully awarded for commercial production by FUKUDA Co., Ltd. ("FUKUDA") for its Air Leak Test System for package containers MSQ-2000 series.

Figure 1: Air Leak Test System MSQ-2000 using Elephantech's P-Flex®

P-Flex® is used in the pressure sensor module which plays a pivotal role in the Air Leak Test System.

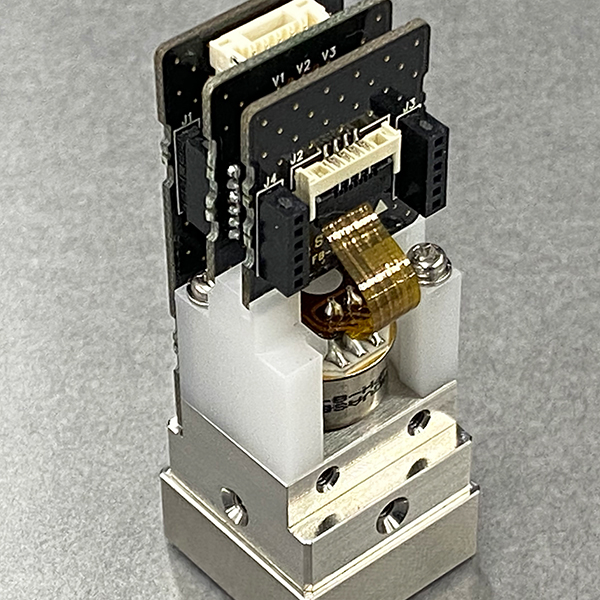

Figure 2: The pressure sensor module using Elephantech's P-Flex®

Air leak test system deploys multiple pressure sensors in high density space and hence such modules need to be small. Typically, initial cost of flexible circuit boards can be a big issue depending on the lot size, and there are many cases where there is no choice but to use cable wiring that takes up a lot of space. Elephantech's P-Flex® was awarded for this system as its manufacturing method substantially reduces costs both of mass production and development regardless lot size while also allowing for the miniaturization of the module.

The following comments were made by a FUKUDA personnel in charge of development.

“By adopting P-Flex®, we were able to reduce the footprint of our high-precision pressure sensor module by more than 30% compared to conventional models. With a single P-Flex® replacing and simplifying several cables, we were able to reduce the total number of components and shorten assembly procedures. We would like to thank Elephantech for all the support we received in the development of this product.”

The Leak Test System made by FUKUDA is the-state-of-the-art so that it allows full inspection (100% inspection) in efficient and quantitative manner, which may replace the conventional water-in-dunk & bubble testing (sampling inspection). The fact that FUKUDA, a leader in this field, has adopted P-Flex® and Elephantech can contributes in medial and food safety is encouraging for Elephantech.

The P-Flex® manufacturing method (Elephantech's own Pure Additive™ processing) stands out for its use of inkjet printing to form a seed layer (silver nanoparticles) where necessary and high-speed electroless copper plating to form the wiring. In comparison with conventional printed circuit board manufacturing methods, Elephantech's manufacturing method can greatly contribute to the reduction of environmental impact as it not only eliminates metal waste by forming the circuitry only where necessary but also as it forgoes the need for etching (a surface treatment technique that utilizes the corrosive effects of chemicals).

Elephantech will continue to develop further technologies while striving to improve quality, cost, delivery and service.

Reference:

FUKUDA Co., Ltd.’s Air Leak Test System for Packaging Containers

https://www.fukuda-jp.com/en/product/f08/

*This product is only available in Japan.

Company Overview

| Name | Elephantech Inc. |

| Establishment | January 2014 |

| Headquarters | 4-3-8 Hatchobori, Chuo-ku, Tokyo 104-0032, Japan |

| Representative | Shinya Shimizu, CEO |

| Capital | JPY 100 million |

| Number of employees | 61 |

| Business Description | Development of printed electronics manufacturing technology and provision of related services |

| URL | https://www.elephantech.co.jp/en/ |

As of November 4, 2021

Contact for inquiries regarding this matter

Elephantech Inc. Public Relations