May 13, 2021

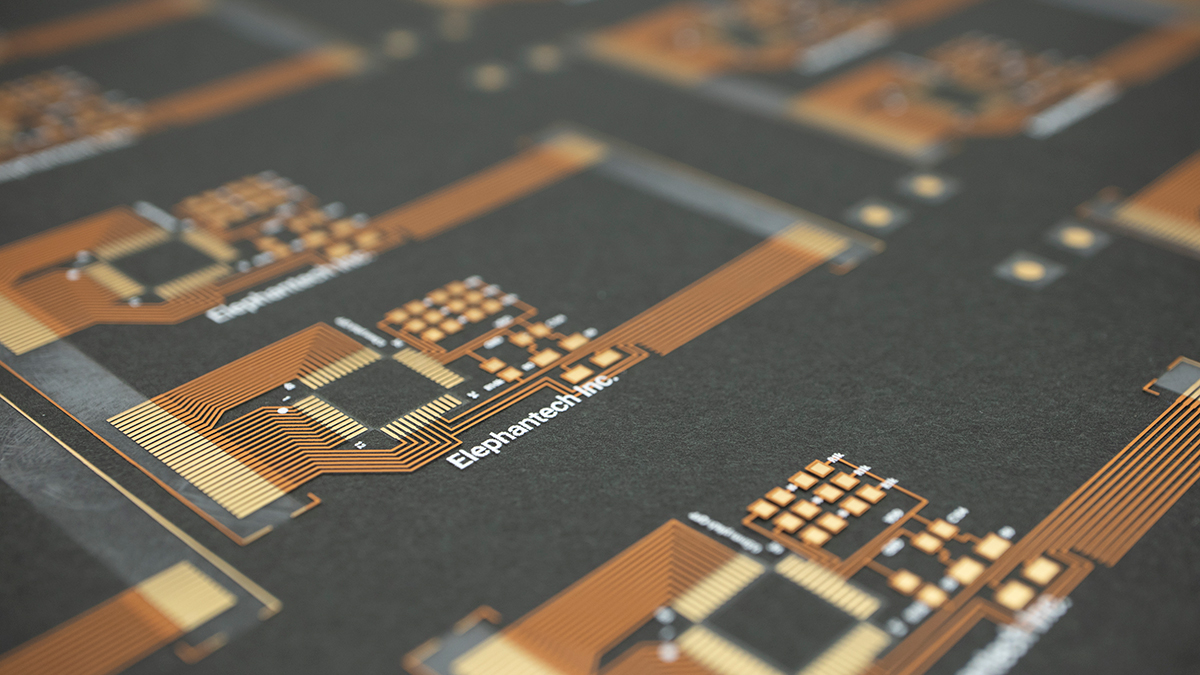

Elephantech Inc.

Elephantech Announces Launch of P-Flex® PI

Utilizing Laser Ablation and Inkjet Technologies

Elephantech Inc. (head office: Chuo-ku, Tokyo, CEO: Shinya Shimizu, hereinafter “Elephantech”) is pleased to announce that the company has started production of P-Flex® PI utilizing laser ablation and inkjet technologies on May 13th.

3 key points of the P-Flex® PI utilizing laser ablation and inkjet technologies

Background

Following the rapid rise of IoT and AI, demand for flexible printed circuit boards (Flex PCB) with ever finer line spacing is also on the ascent. In order to meet such demands for fine Line/Space Flex PCBs, Elephantech has decided to launch P-Flex® PI which combines laser ablation and inkjet printing.

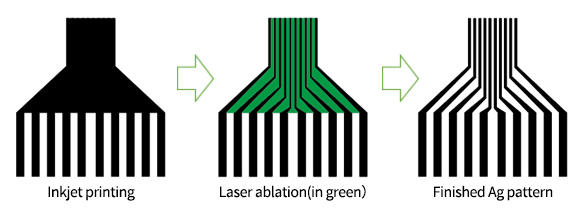

Elephantech’s Flex PCB production process mainly consists of the following 3 stages,

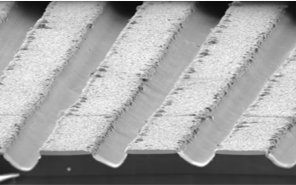

- Inkjet printing of Ag nano particles

- Laser ablation to remove unnecessary parts of the printed Ag

- Addition of a copper electroless plating onto the Ag layer

Although laser ablation has long been considered as a potential means to achieve finer line spacing in Flex PCBs, there had been question marks over its suitability for mass production due to its long processing time. However, with its high accuracy inkjet printing technologies, Elephantech has succeeded in overcoming this issue by using inkjet printing to reduce the laser processing area, achieving finely patterned Flex PCBs while maintaining the advantages of being mold-less.

Elephantech is pleased to announce the launch of a Polyimide based Flex PCB with a minimum Line/Space of 100/100μm, and will continue to focus on developing Flex PCBs with even finer line spacing. For any inquiries regarding this new product or the progress of its development, please feel free to contact Elephantech’s P-Flex Sales department.

On a mission to making a sustainable world through new manufacturing technologies, Elephantech strives to serve its customers and drive the electronics industry forward.

The results of this research were obtained in part from a project subsidized by the New Energy and Industrial Technology Development Organization (NEDO).

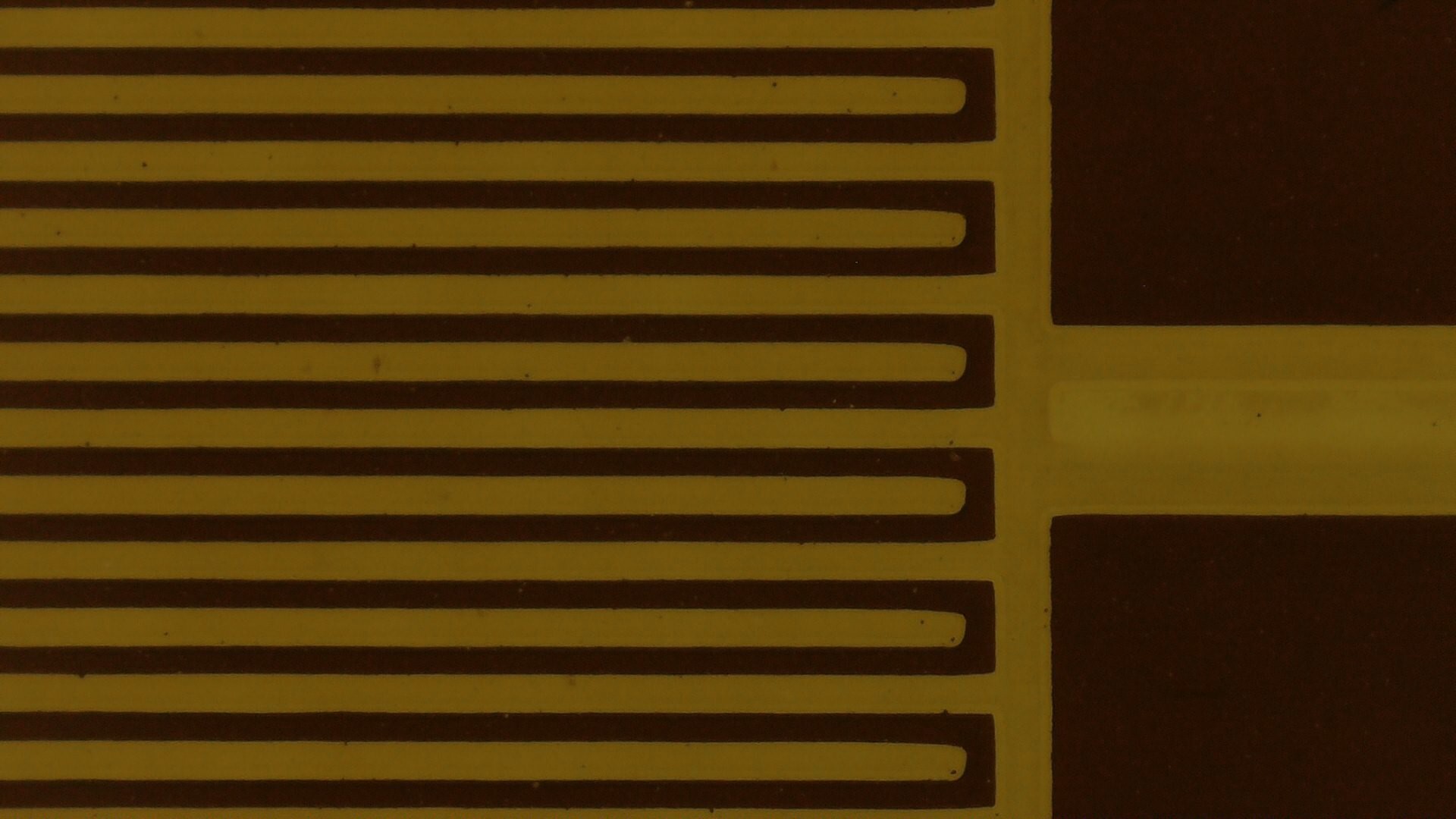

Flex PCB with line & space of 100/100μm

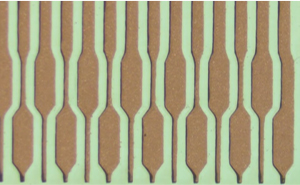

Left : 0.2mm pitch staggered connector (under development)

Right : Flex PCB with line & space of 50/50μm (under development)

Company Overview

| Name | Elephantech Inc. |

| Establishment | January 2014 |

| Headquarters | 4-3-8 Hatchobori, Chuo-ku, Tokyo 104-0032, Japan |

| Representative | Shinya Shimizu, CEO |

| Capital | JPY 100 million |

| Number of employees | 51 |

| Business Description | Development of printed electronics manufacturing technology and provision of related services |

| URL | https://www.elephantech.co.jp/en/ |

As of May 1, 2021

Contact for inquiries regarding this matter

Elephantech Inc. Public Relations