February 17, 2021

Elephantech Inc.

Elephantech Starts Operations at its Large Mass-Production and Research Complex

Elephantech Inc. (head office: Chuo-ku, Tokyo, CEO: Shinya Shimizu, hereinafter “Elephantech”) manufactures P-Flex®, a Flex PCB that can be produced in an environmentally friendlier manner. Elephantech is pleased to announce that, as of January 2021, the company has started operations at its large mass-production and research complex for P-Flex® ("AMC Nagoya").

<AMC Nagoya>

Having raised a total of JPY 1.8 billion in October 2019 and established a large mass-production and research complex within the Nagoya factory rented from Mitsui Chemicals Co., Ltd. since July 2020, we started production and shipment of prototypes in January of this year and plan to continuously fine-tune our equipment and start production and shipment of mass-produced products in April.

As for production capacity, the monthly production capacity will be 5,000m² in 2021 and we will expand our equipment to secure a monthly production capacity of 20,000m² in 2024. The maximum capital investment amount including this expansion is expected to be JPY 1.4 billion.

With the realization of the world's first large-scale mass production of inkjet-printed electronic circuits and the provisions of inkjet printing technologies by Seiko Epson Corporation and of the factory building and mass-production know-how by Mitsui Chemicals Co., Ltd., we aim to utilize the strengths of large corporations to break down the barriers to mass-production faced by startups.

Although we had already been offering small-scale mass-production in Hatchobori, Tokyo, the beginning of operations at AMC Nagoya as "the world's first large mass-production and research complex using inkjet printing technologies for the production of electronic circuits" allows us to deliver environmentally friendlier and highly cost competitive products to many customers and represents the next step in accomplishing our corporate mission of "Making the world sustainable with new manufacturing technologies."

<Pure Additive™ processing>

<P-Flex®>

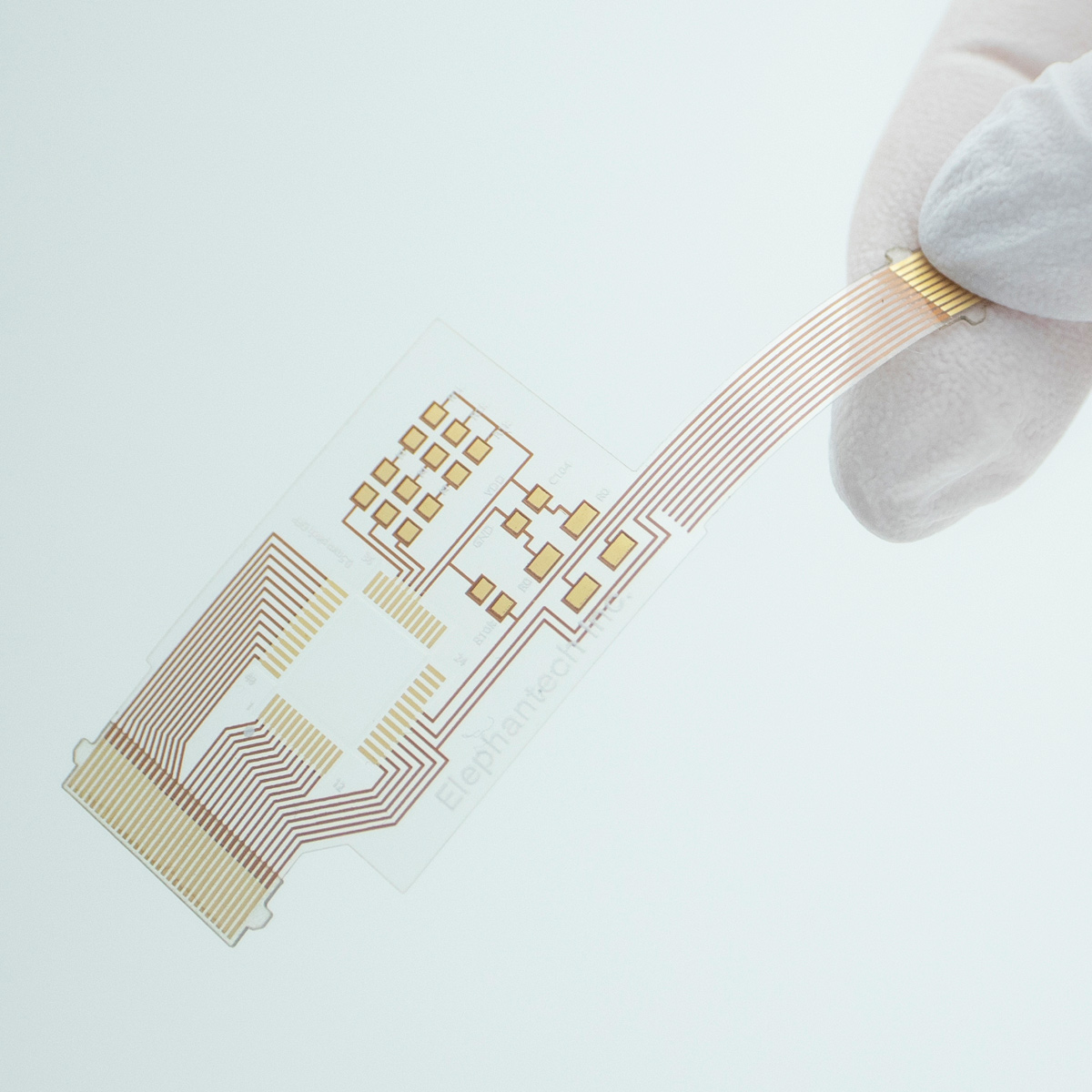

P-Flex® is an environmentally friendly Flex PCB manufactured using the Pure Additive™ processing that uses inkjet printing to only print metals where necessary and plating technology to grow the metal.

This research is based on results obtained from a project subsidized by the New Energy and Industrial Technology Development Organization (NEDO).

We had planned to invite guests and hold an unveiling party to mark the commencement of operations at AMC Nagoya but have had to reconsider the event in respect of health and safety measures and preventing the spread of the novel coronavirus.

Overview of the large mass-production and research complex

| Name | AMC Nagoya |

| Address | c/o Mitsui Chemicals Inc. Nagoya Works, 2-1 Tango-dori, Minami-ku, Nagoya-shi, Aichi 457-0801, Japan |

| Factory manager | Yuji Miwa |

| Start of manufacturing and shipping | Prototypes in January 2021, mass-produced products in April 2021 |

| Investment amount | Up to JPY 1.4 billion |

| Number of employees | 10 (at beginning of operations) |

| Building overview | Total floor area of approx. 2,600㎡, three-storied steel structure |

Company Overview

| Name | Elephantech Inc. |

| Establishment | January 2014 |

| Headquarters | 4-3-8 Hatchobori, Chuo-ku, Tokyo 104-0032, Japan |

| Representative | Shinya Shimizu, CEO |

| Capital | JPY 100 million |

| Number of employees | 48 |

| Business Description | Development of printed electronics manufacturing technology and provision of related services |

| URL | https://www.elephantech.co.jp/en/ |

As of February 17, 2021

Contact for inquiries regarding this matter

Elephantech Inc. Public Relations