Elephantech's Environment-friendly P-Flex® Flex PCB Adopted for DaikyoNishikawa Corporation's Bumper Millimeter-wave Radar Concept

Japanese English

Elephantech Inc. (Headquarters: Chuo-ku, Tokyo, CEO: Shinya Shimizu, hereinafter "Elephantech") is pleased to announce the adoption of its P-Flex® Flex PCB by DaikyoNishikawa Corporation.

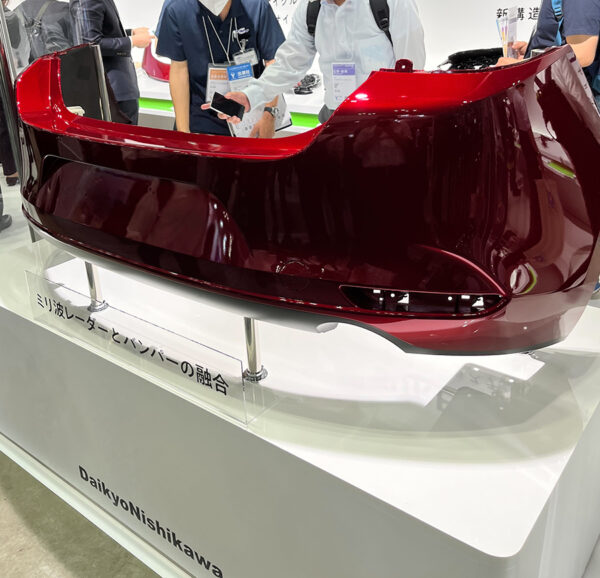

DaikyoNishikawa Corporation exhibited its bumper millimeter-wave radar concept at the Automotive Engineering Exposition 2022 YOKOHAMA and selected our P-Flex® as an environment-friendly Flex PCB.

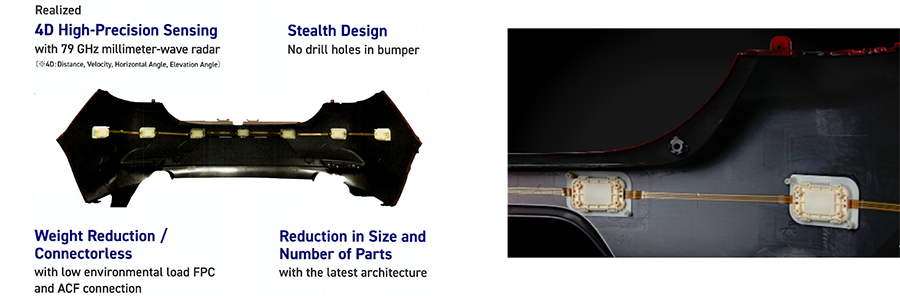

P-Flex® was adopted in the connectors between millimeter-wave radar boards behind the bumper.

Compared to cameras and other anti-collision measures, millimeter-wave radars have advantages such as longer measurable distances and better performance at night or in bad weather conditions.

While millimeter-wave radars are, in general, densely packed in the front of a car for its desired obstacle detection function, the front bumper is also the part of the vehicle that attracts the most attention from a design perspective – in other words, the detection function must be achieved without compromising design. In addition, it is essential to reduce size and weight to reduce CO2 emissions.

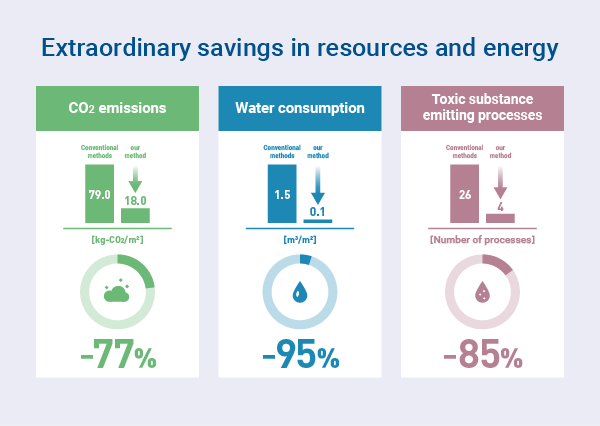

Flex PCB is highly suited to such needs, and DaikyoNishikawa selected P-Flex® because our Pure Additive™ processing method can flexibly accommodate design changes and has an overwhelmingly low environmental impact compared to existing Flex PCB manufacturing methods.

We have received the following comments from a person in charge of development at DaikyoNishikawa Corporation:

"The concept is a stealth design without drill holes on the bumper. The multiple cables, which can be a problem when using wiring harnesses, are integrated into a single P-Flex®, allowing a weight reduction. As well as the improvement in fuel efficiency by weight reduction, P-Flex® consumes far less energy to manufacture compared to other companies' Flex PCBs.

We are happy to be able to develop a very eco-friendly product and would like to thank Elephantech for its great cooperation."

DaikyoNishikawa Corporation's bumper millimeter-wave radar is a product that combines mechanical & electrical design along with software technology, and we are encouraged by their adoption of P-Flex® for their advanced concept model.

The P-Flex® manufacturing method (Elephantech's Pure Additive™ processing) stands out for its use of inkjet printing to form a silver nanoparticle seed layer where necessary and high-speed electroless copper plating to form wirings. In comparison with conventional printed circuit board manufacturing methods, Elephantech's manufacturing method can greatly contribute to the reduction of environmental impact as it not only eliminates metal waste by forming the circuitry only where necessary but also as it forgoes the need for etching (a surface treatment technique that utilizes the corrosive effects of chemicals).

Elephantech will continue to further develop technologies while striving to improve quality, cost, delivery, and service.

Company Overview

| Name | Elephantech Inc. |

| Establishment | January 2014 |

| Headquarters | 4-3-8 Hatchobori, Chuo-ku, Tokyo 104-0032, Japan |

| Representative | Shinya Shimizu, CEO |

| Capital | JPY 100 million |

| Number of Employees | 73 |

| Business Description | Development of printed electronics manufacturing technology and provision of related services |

| URL | https://www.elephantech.co.jp/en/ |

As of June 1, 2022

Contact for inquiries regarding this matter

Elephantech Inc. Public Relations

pr@elephantech.co.jp