Joint Development with NICCA CHEMICAL of “Neochromato Process” Polyester Fabric Discharge Printing Technology for Zero-Waste Fashion

Japanese English

Elephantech Inc. (“Elephantech”) is pleased to announce the joint development with NICCA CHEMICAL CO., LTD. (“NICCA CHEMICAL”) of the “Neochromato process” polyester fabric discharge printing technology with the aim of achieving zero-waste in fashion textile.

As the momentum to reduce greenhouse emissions gathers pace, there is a growing trend toward greater consideration of society’s impact on the environment. According to the Ministry of the Environment, “the fashion industry has been identified as having a significant impact on the environment due to the amount of energy required for its production and the shortness of its product lifecycle, making it a global issue” that needs addressing, and sustainable approaches moving away from the current mass production, mass consumption and mass disposal have been brought into focus.

The Neochromato process jointly developed by Elephantech and NICCA CHEMICAL contributes greatly towards reducing the industry’s environmental impact and has the following characteristics:

- Allows discharge printing on polyester fabric dyed with disperse dye

- Sublimation transfer printing process allows the discharge and print process to be repeated on the fabric immediately after the initial discharge

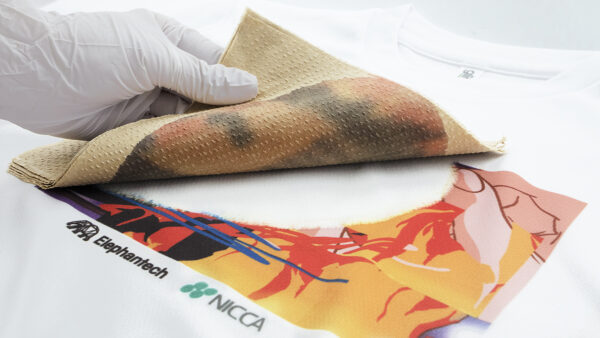

Water-less discharge printing has been successfully achieved by removing the dye from the polyester fabric and transferring it to a backing paper. This backing paper used to collect the dye can be disposed of as burnable waste, minimizing wastewater pollution and making the technology sustainable.

Furthermore, the sublimation transfer printing process can be used on discharge printed fabrics, allowing for the discharge and printing process to be repeated immediately after the initial discharge. This contributes not only to expanding the scope of expression for polyester-based fabrics but also to increasing upcycling possibilities for clothing and other fabric-based products.

The process was perfected with its easy implementation in mind, requiring no other equipment than a heat press machine used for sublimation transfer printing and allowing most factories and workplaces to use it immediately.

Comments from the development team

NICCA CHEMICAL:

We started our spontaneous, in-house extracurricular manufacturing club called “MO-SO (fantasy) Meeting” after being inspired by Elephantech Vice President Masaaki Sugimoto’s lecture at our innovation center. The development of this technology first began when Masaaki Sugimoto and Aguri Sagimori showed interest in a MO-SO Meeting experiment which involved blurring characters and patterns to make them indistinguishable. We then obtained the cooperation of Japan Polymark when considering practical applications of the technology. We named the technology "Neochromato process" after how the dispersed dye that shouldn’t wash off would mysteriously seep through and be transferred as if in paper chromatography. We hope to convey to the world our desire to reduce textile waste through upcycling and to use as little water as possible while doing so.

Elephantech:

The development of this technology came about following a conversation we had with the artist Aguri Sagimori in which we realized that there could be a huge amount of clothing waste from the fashion industry should the Tokyo 2020 Summer Olympics be postponed and rebranded as TOKYO 2021, and that we somehow needed to develop a technology to upcycle it all. As it happened, the event was postponed but thankfully kept its TOKYO 2020 naming, avoiding the mass waste we feared. However, we also came the see that the fundamental issue was how many pieces of clothing are only worn few before being disposed of anyway, and so we continued our trial-and-error process along with many stakeholders in order to perfect the technology. As a result, we ended up with a magical technology that can erase and reprint prints over and over again.

We hope that this Neochromato process technology will be used by many and contribute in bringing an era where we can enjoy sustainable fashion.

Future Outlook

The Neochromato process requires no equipment other than a heat press machine. In fact, in skilled hands, a simple clothes iron may suffice. In addition, water-less discharge printing on polyester is also possible with some backing paper and processing solution, although there remains the constraint of various parameters such as the type and quantity of the backing paper and the processing temperatures needing some fine tuning depending on the kind of fabric it is used on and the amount of dye. In order to boost user adoption of the Neochromato process, we plan to start by proposing a PoC (Proof of Concept) project for the circular economy in which we will accompany our customers.

References

Related Pages

Polyester Textile Decolorization Technology “Neochromato Process.”

The Neochromato Process is a polyester textile decolorization technology jointly color changes to fabrics for improved reusability.

Company Overview

| Name | NICCA CHEMICAL CO., LTD. |

| Establishment | September 1941 |

| Headquarters | 23-1, 4-chome, Bunkyo, Fukui-city, Fukui 910-8670 Japan |

| Representative | EMORI Yasumasa, President |

| Capital | JPY 2,898 million |

| Number of Employees | Consolidated : 1,454 (As of December 31st, 2021) |

| Business Description | Manufacturing and sales of surfactants, cosmetics and pharmaceutical products |

| URL | https://www.nicca.co.jp/en/ |

| Contact for inquiries regarding this matter | NICCA CHEMICAL CO., LTD. Public Relations info@niccachemical.com |

| Name | Elephantech Inc. |

| Establishment | January 2014 |

| Headquarters | 4-3-8 Hatchobori, Chuo-ku, Tokyo 104-0032, Japan |

| Representative | Shinya Shimizu, CEO |

| Capital | JPY 100 million |

| Number of Employees | 73 |

| Business Description | Development of printed electronics manufacturing technology and provision of related services |

| URL | https://www.elephantech.co.jp/en/ |

| Contact for inquiries regarding this matter | Elephantech Inc. Public Relations pr pr@elephantech.co.jp |

As of April 1, 2022